SDG6

Clean Water and Sanitation

SDG6

Clean Water and Sanitation

Water consumption on campus

Water extraction, consumption, and tracking

Reports to THE Impact Ranking indicators 6.2.1, 6.2.2 & 6.5.4

To provide the university and local community with potable water, KAUST owns and operates a Seawater Reverse Osmosis Desalination (SWRO) Plant with a 52,520 m³/day production capacity. The plant produces, monitors, and tracks the potable water provided to the academic campus and the local community surrounding KAUST. The quality of the produced water is routinely tested by the Facilities Management Utilities team (FM Utilities), to ensure maximum quality and security.

KAUST's Seawater Reverse Osmosis Desalination Plant

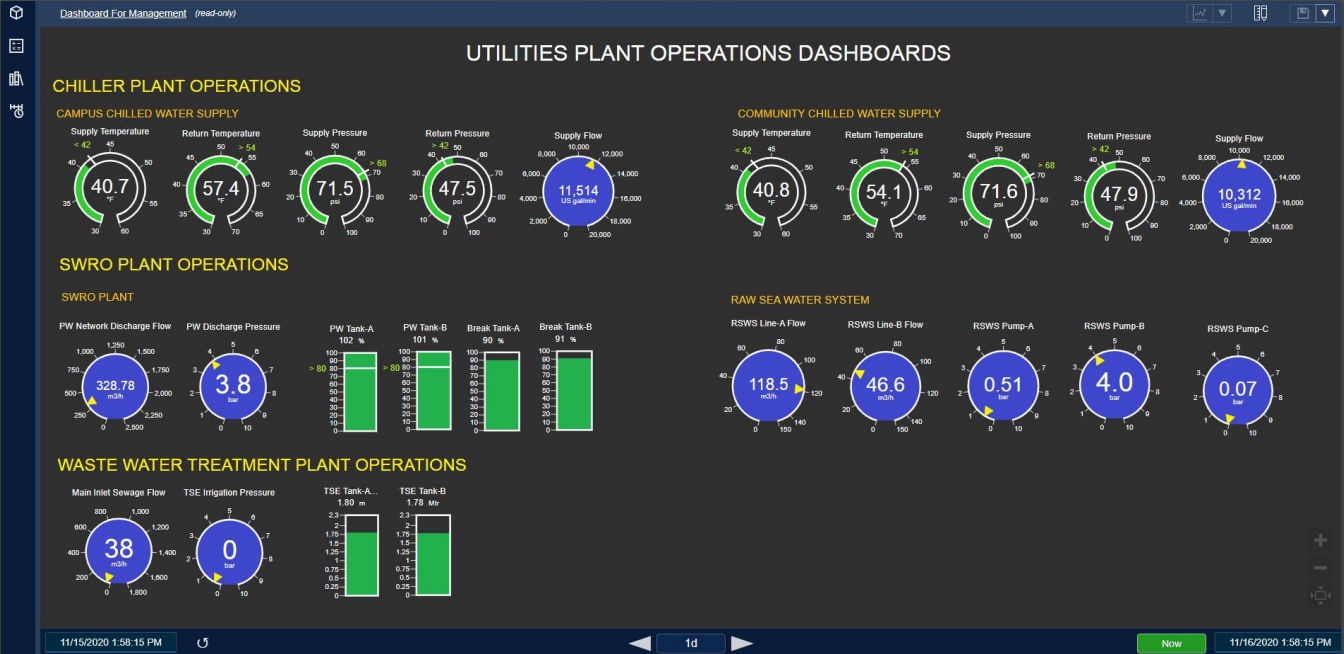

FM Utilities Plant Operations Dashboard at the KAUST Utility Plant, which showcases in real-time the amount of potable water being produced, as well as the amount of Treated Sewage Effluents (TSE)

Currently, some improvements are being implemented by the FM Utilities team to the KAUST SWRO plant, in order to improve the capacity, efficiency, and reliability of the system. Some of the improvements include a plant expansion for additional production of 9,000 m³/day; redundant seawater supply to SWRO Plant; redundant reject line; and additional turbidity sensors and valves to improve the effectiveness and life span of the spruce media filter and reverse osmosis membranes.

KAUST also explores more sustainable ways of performing water desalination at its Water Desalination and Reuse Center (WDRC). One successful example is KAUST-based company MEDAD's pilot solar-powered desalination installation. The hybrid MEDAD cycle technology desalinates seawater at a temperature of 60 - 80 degrees Celsius using renewable solar energy.

MEDAD's solar-powered and fully automated desalination pilot plant facility at the Water Desalination and Reuse Center (WDRC)

By installing a setup of 352 m² evacuated tube solar collectors on the rooftop of one of KAUST's buildings, MEDAD was able to produce 10,000 L of desalinated water per day. The technology has the advantage of achieving performance levels of 20% vs compared to 10-13% of conventional desalination technologies. This efficiency translates into water production costs of $0.48/m³ versus other distillation processes which averagely cost $1.201/m³. The technology was distinguished with the Sustainability Medal 2020 at the MEED Projects Awards and is currently being implemented in other institutions.

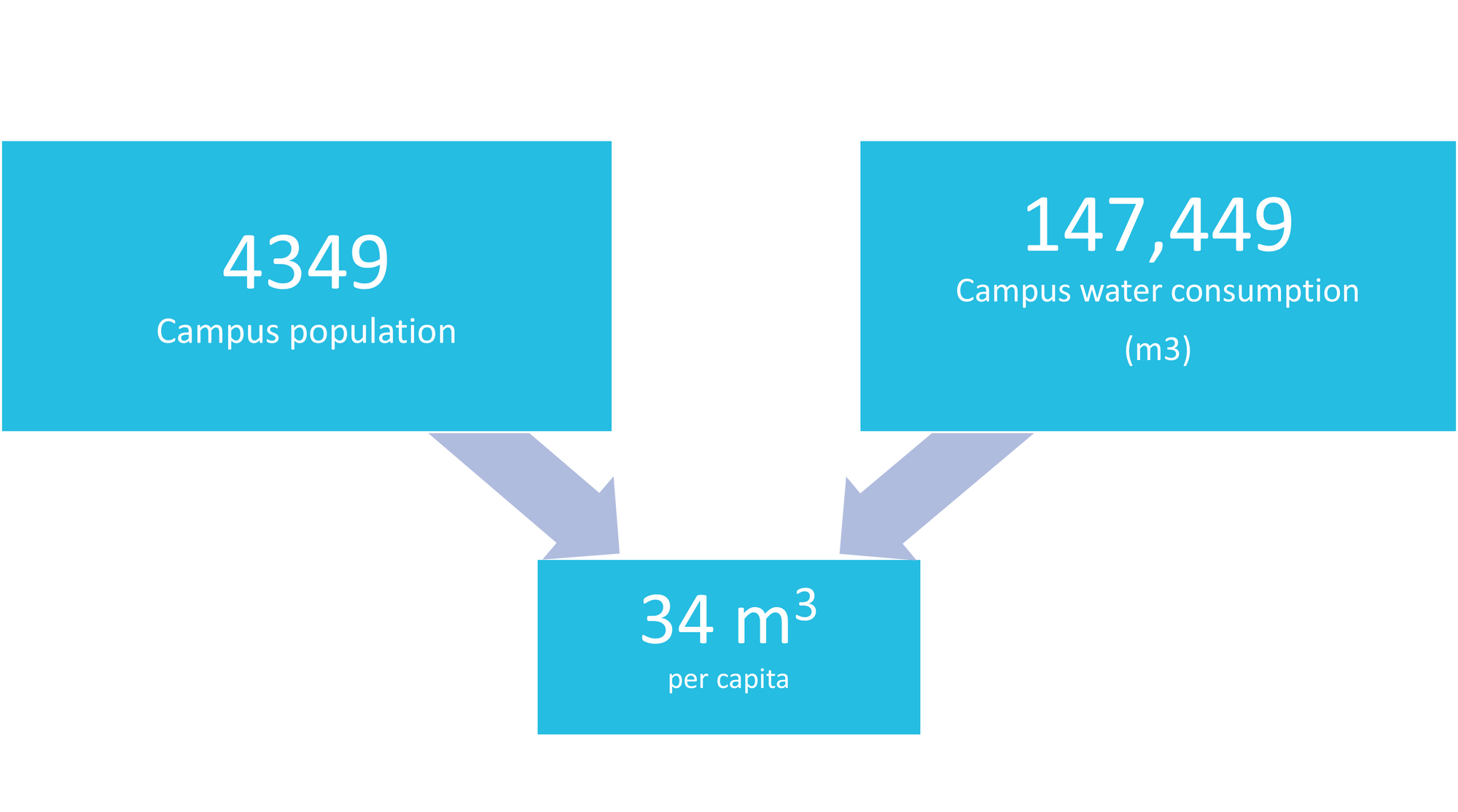

Overall, in 2019, 147,449 m³ of potable water was utilized by the KAUST academic campus. The campus population is considered as the sum of all students, faculty, staff, and contractor workforce that develop their day-to-day activities on campus grounds.

Water usage and care

Wastewater treatment

Reports to THE Impact Ranking indicator 6.3.1

Like most resources on our planet, water should be reused whenever possible. All wastewater, comprising stormwater, gray water, and black water from KAUST's academic campus and surrounding community, is collected and channeled to the KAUST Wastewater Treatment Plant (WWTP) for treatment and reuse as irrigation water.

KAUST Wastewater Treatment Plant

The KAUST WWTP is a state-of-the-art plant capable of treating 11,500 m³ / day of effluents using Membrane Biological Reactor (MBR) treatment technology. Supervising the plant, the FM Utilities team ensures that the produced Treated Sewage Effluents (TSE) meets high-quality specifications and is up to international standards.

Additionally, KAUST has also explored the possibility of using the condensate water from air handling units in the campus buildings as irrigation water. After the conclusion of the feasibility study, it was projected that KAUST could reach 50-100% reduction in potable water within the West Quadrant irrigation systems of the academic campus. Further design development is currently being evaluated.

Preventing water system pollution

Reports to THE Impact Ranking indicator 6.3.2

As part of its Environmental Stewardship Policy, KAUST pledges to protect the precious marine environment surrounding the University and eliminate or minimize the adverse environmental impact of its operations.

The HSE Wastewater Management Procedure outlines the processes to prevent polluted water from entering the marine environment. The procedure regulates all discharges that are relevant to KAUST operations based on risk assessment, and include "Marine Outfall Management, Direct Discharge, Washing/flushing/testing discharges, Dewatering, Marine Vehicle Sewage, Wastewater Reuse, Septic Tank and F.O.G". The procedure also includes "Water Quality Monitoring Requirements".

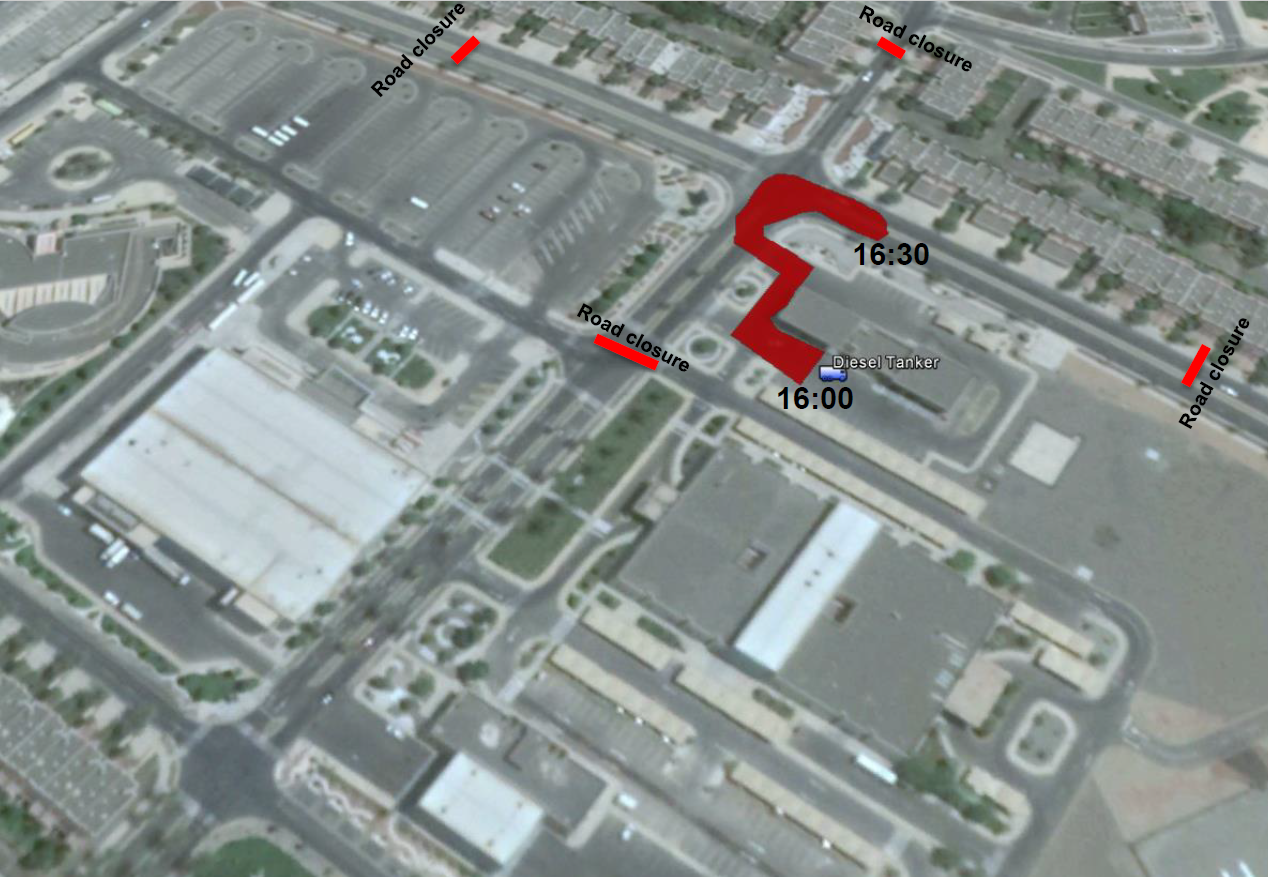

Moreover, HSE routinely carries several actions to prevent water system pollution such as oil spill emergency drills or by performing construction/renovation project reviews during the design and construction phases, and as applicable, to provide design guidelines/comments that may prevent water pollution.

Example of Oil Spill Emergency drill carried by HSE

Weekly monitoring of a KAUST water body

In addition, KAUST routinely tries to implement efficient and sustainable biological control measures in its water bodies. In June 2020, the Horticulture & Pest Control Services implemented a new strategy using biological methods to control mosquito larvae in lakes and ponds of KAUST, using the locally adapted mangrove fish Aphanius dispar, or Arabian toothcarp.

After ten weeks of introducing this local species, the pilot bodies of water have never tested positive for mosquito larvae to date, and a stable fish population has been established.

This successful adaptation of biological control equated to an 83% reduction of pesticide consumption in controlling mosquito larvae in water bodies throughout KAUST, heavily reducing the environmental impact on water bodies and overall fauna.

Potable water fountains and refilling stations

Reports to THE Impact Ranking indicator 6.3.3

Bottle Refilling signs at the Campus Diner Photo: N.Nason

In order to discourage the use of single-use plastics and optimize drinking water usage, KAUST has implemented free water refill stations (ezH2O Bottle Filling Stations) scattered across campus. These fountains are present in every building and at the Campus Diner to encourage students, staff, and visitors to bring their reusable bottles and refill them at their own needs, eliminating unnecessary plastic and water waste.

ezH2O Bottle Filling Stations available at each building on the academic campus. Photo: N Nason

Community announcement on the ban of single-use plastic bottles at several campus locations (2019)

In addition, the KAUST Community Life department launched a community-wide campaign to eliminate plastic water bottles from the campus diner and food outlet providers. This initiative encourages staff, students, and guests to bring their reusable water bottles (or use supplied glass cups). As part of this campaign, additional free water coolers were installed in many of the food outlets.

Water-conscious campus buildings

Reports to THE Impact Ranking indicator 6.3.4

LEED Platinum KAUST Campus

KAUST has been committed to implementing sustainable and conscious building standards since its genesis. The KAUST Campus is LEED Platinum Certified for New Construction and was the largest LEED Platinum project completed back in 2009. The LEED certification encompasses a series of standards which include water efficiency standards. Moreover, KAUST's Facilities Management Planning, Design, Engineering & Construction team (FM PDEC) ensures all new and renovated buildings at KAUST meet construction standards that equate to a minimum LEED Gold for New Constructions.

As part of its own Sustainability Design Criteria for new construction, KAUST also addresses Water Efficiency by laying out specific pre-requisites for any building developed not only on campus grounds but also in the surrounding community. Some of these requisites include, but are not limited to, indoor water use reduction, water metering, greywater usage, or outdoor water use reduction.

Water-conscious landscaping

Reports to THE Impact Ranking indicator 6.3.5

Examples of xeriscaping and water conscious-planting across KAUST campus and community

To reduce the daily irrigation water consumption, the KAUST Horticulture & Pest Control Services has conducted a full review of the landscaping at KAUST since 2015. Accordingly, significant landscaping optimization was implemented at more than 100 sites by implementing xeriscaping design concepts, both on campus and surrounding residential community.

The conversion of part of the potable irrigation network to Treated Sewage Effluent (TSE) together with the landscaping optimization and xeriscaping efforts, including an irrigation Shut Off day, and the residential backyard side optimization, resulted in significant irrigation water reduction by almost 50% when compared to the year of 2015.

Moreover, another benefit of the carried optimization was minimizing pollution by eliminating the need for grass mowing, chemical fertilizers, pesticides and reducing maintenance requirements at optimized sites.

The preserved flora-containing landscape comprises a worldwide collection with more than 144 plant species, from which 101 (70%) are drought-tolerant plants, fitting the dry environment of the region.

Edama featured at local news outlet Arab News (2020)

KAUST has also partnered with the start-up EDAMA, which produces compost products with increased water retention and tailored for the desert environment, out of organic waste. Following the success of Edama's pilot composting facility, KAUST has signed a contract with the company to build a commercial-scale composting facility, which will be responsible to manage 96% of KAUST's organic waste. By using the resulting Edama's Premium Soil Improver, which can reduce irrigation water use up to 75%, KAUST will realize significant water savings in its non-TSE irrigated landscape.

Water reuse and recycling

Campus water reuse policy and monitoring

Reports to THE Impact Ranking indicator 6.4.1 & 6.4.2

From its design inception, KAUST collects all wastewater and treats it for reuse as irrigation water. In order to ensure there is a plan in place for water reuse, the Facilities Management Utilities team has a protocol in place to use TSE water produced by the KAUST Wastewater Treatment Plant. The protocol, in place since 2017, sets out the guidelines for different operation teams to follow in case of overproduction and/or underproduction of TSE water.

The Facilities Management Utilities Unit Plant measures all reused water at KAUST. The treated wastewater (TSE) product is usually tested three times daily at an in-house laboratory, which is supported by a biweekly test from a third-party laboratory.

The average TSE produced annually by the KAUST WWTP is around 1.6 million m³, with the average daily inlet effluents being 4,500 m³/ day.

KAUST is proud to have 100% of its produced TSE to be reused to irrigate green areas across the academic campus and surrounding community.

Irrigation using TSE at KAUST green area.

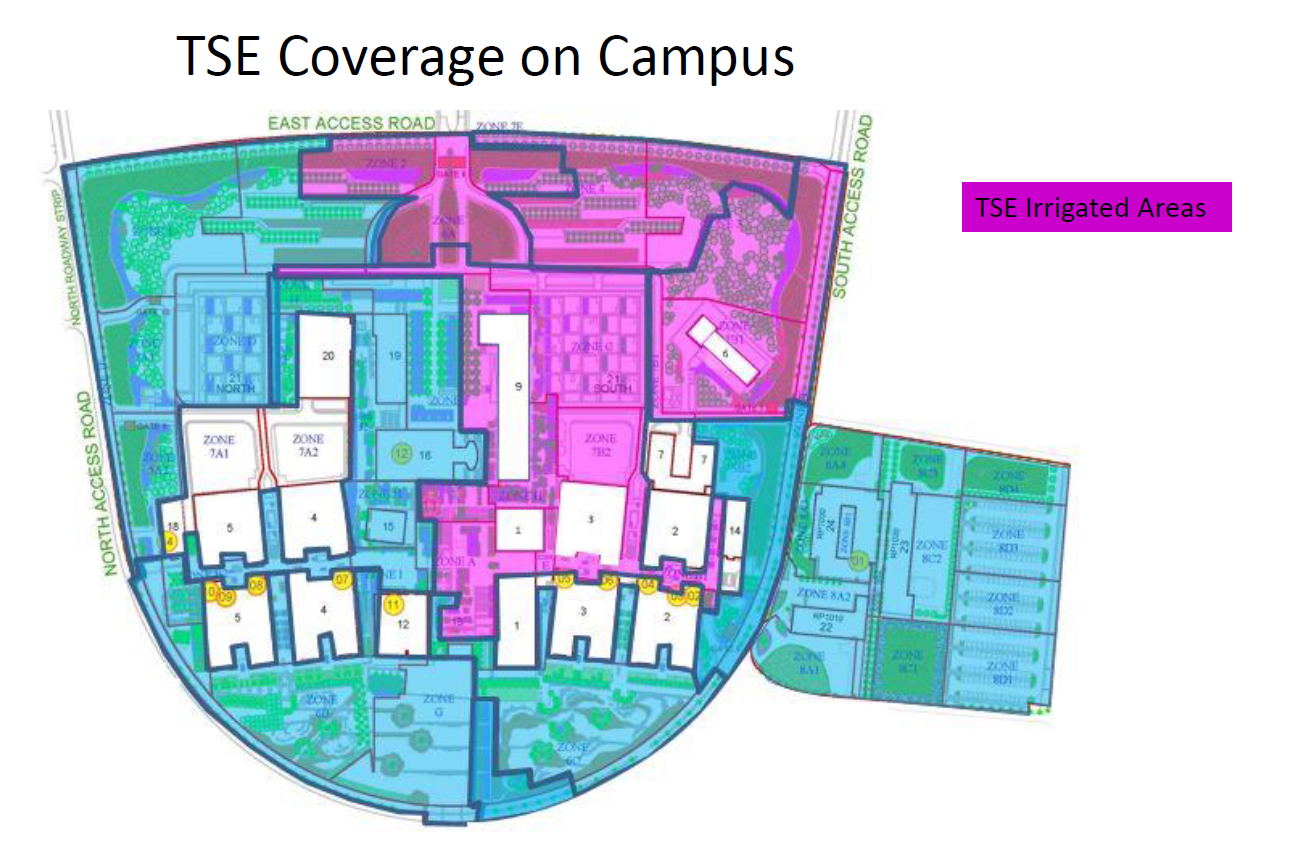

Current TSE irrigation coverage at the academic campus

In summary, 35% of the total irrigation water used daily for all landscaping at KAUST comes from TSE, and so does 38% of the daily total irrigation water used for the academic campus.

Water in the community

Education in water management

Reports to THE Impact Ranking indicator 6.5.1 & 6.5.3

Local KAUST School student presenting a project on Hydroponics at a community open event

KAUST provides educational opportunities for local and national communities to learn about international best practices in water management by organizing different scientific conferences and workshops. For example, the Water Desalination and Reuse Center organizes conferences open to the local KAUST community, student body, and national stakeholders and institutions.

Another example of programs involving local school children is the Science Summer Camps organized by the Social Responsibility team. In 2019, a Wastewater Workshop for students from the local communities of Thuwal and Jeddah was taught by KAUST Professor Peiying Hong – a highly recognized international scholar on Water Desalination and Reuse. Students had the opportunity to meet and learn directly from a reputable scholar about wastewater and overall water conservation and management.

Sci-Café on Water Security (2019). The Sci-Café is a live-streamed, community-open discussion forum where KAUST faculty are invited to talk about their expertise on key development subjects and foster healthy discussions between all members of the community

KAUST also encourages local community members to learn about the current research done in water management practices by organizing lab visits, awareness campaigns, podcasts, and public discussions around the importance of water for the region and the world.

Promoting conscious water usage

Reports to THE Impact Ranking indicator 6.5.2

KAUST promotes best practices on water efficiency and reduction throughout its campus and surrounding community. During the 2018-19 academic year, the Facilities Management department initiated the 'Water Saving Project'. Through the implementation of efficient water-saving kits, the project aimed at reducing water consumption by:

- Replacing all conventional water fixtures from the academic campus with water-saving fixtures that reduce the water flow between 40% to 55%;

- Ensuring all faucets at the academic campus are equipped with touchless automatic motion sensors, ensuring minimal water wastage;

- Installing displacement tanks in all academic campus toilet flushers, reducing the volume of water used at every discharge.

Community-wise, KAUST also expanded its water-saving efforts by installing water-saving kits across all community residential units. In the two most recently opened community residential areas, comprising 582 of the total 2,740 residential units, water-saving measures were built into the designs by the Facilities Management Planning, Design, Engineering & Construction (FM PDEC). Regarding students' apartments, water-saving measures have been designed into the renovation program of 996 units.

Furthermore, the Community Life Accommodation Services team started a program to actively encourage and promote the replacement of sod lawns (at the sides of properties) with gravel to reduce the volume of water needed for irrigation.

In terms of food service, food providers at KAUST must follow strict guidelines for water reduction. Guidelines include installing foot-pedal/sensor handwash stations and maintaining all kitchen equipment to minimize and report any water leakage.

Cooperation on water conservation and security

Reports to THE Impact Ranking indicator 6.5.5

KAUST actively collaborates on water security issues with local, regional and national governments, as well as industry partners. To cement the vision of cross-sectoral partnerships, the Water Desalination and Reuse Center has implemented the Center Industry Affiliates Program (CIP). The program aims to create strong collaborations between academia, industry, and government to transform Saudi Arabia into a more innovative, knowledge-based economy, while securing its hydric resources.

As part of this network, entities such as the Saudi National Water Company (NWC) and the Saline Water Conversion Corporation (SWCC) -a Saudi Government Corporation - have partnered with KAUST to advance water desalination using innovative and cost-effective desalination technologies, and the development of brine mining technologies.

Signing ceremony of the memorandum of understanding with ACWA Power, inaugurating the KAUST – ACWA Power Center of Excellence for Desalination and Solar Power (2019). Kevin Cullen (left), vice president of KAUST Innovation & Economic Development, and Paddy Padmanathan (right), president and CEO of ACWA Power. File photo

Moreover, KAUST has entered several important memoranda of understanding with other entities such as ACWA Power, one of the world's leading independent developers, investors, and operators of power generation and desalinated water plants. Other entities include the Public Utilities Board (PUB, Singapore), the Middle East Desalination Research Center (MEDRC, Oman), the Centro de Investigaciones Energéticas, Medioambientales y Tecnológicas (CIEMAT, Spain), the Institut de la Filtration et des Techniques Séparatives (IFTS, France), among others.